Our Health, Safety, Security and Environment (HSSE) Manager Lee Deponeo heads up our work to safeguard best practice across the business. His team ensures the very highest standards are upheld as we develop the sustainable energy hub of the future.

Lee has more than 15 years’ experience in the health and safety department at Stanlow refinery, having held positions with Essar Oil UK and Shell. He also studied H&S management at university.

Q: Why is health and safety a key concern at STL?

A: Health and safety has always been our number-one priority at STL.

We’re the UK’s largest liquid storage business handling high volumes of potentially hazardous materials with up to 500 road movements per day. That means that it’s critical for us to have the most robust health and safety processes to minimise any risk to our people, the local community and the wider environment, as well as the financial and reputational risks to our business.

Operating safely is also commercially critical for STL, as customers value reassurance that we have strict processes in place and are committed to being best-in-class.

As a critical step in the supply chain for fuelling the regional economy, we play a key part in helping to lead the UK’s transition to low carbon fuels, another reason that it’s imperative that we make no compromises when it comes to health and safety.

Q: How does STL protect people and the environment?

A: We manage health and safety in three key areas, field safety, process safety and environmental performance.

Field safety covers everything we do to ensure people always work safely on site. This is the basics of safety – do our people have the right tools and equipment to complete their work without incident? Has the task been planned and prepared to the correct standards, and has proper communication taken place to ensure we are able to work safely?

Process safety means applying state-of-the-art expertise to make sure that safety is engineered into every part of every process.

When it comes to environmental performance, we’re committed to ensuring STL has zero impact on anybody on or off-site, so we closely monitor the performance of our equipment to ensure we are compliant with all environmental regulations.

Q: How do you see the health and safety requirements of STL changing in the future?

A: We are committed to lead the national charge in the development of a more sustainable energy infrastructure by creating the UK’s first eco-friendly Energy Hub. We’ll do this through a combination of our unique geographical location, decades of experience and a passion for a greener, cleaner planet.

This also means we’re required to take all measures necessary to prevent major accidents, and ensure precautions are in place to reduce the consequences should an accident take place.

STL’s growth means we’re transitioning from lower to upper tier operator under the Control of Major Accident Hazards (COMAH) regulations. This will mean closer working with the regulator, and increased expectations on our performance.

As we grow, agility in our operations will be essential, and our health and safety processes will need to be able to adapt quickly to ensure we’re always operating to the very highest standards.

Related News

A Day in the Life of Alyssa Usman, Quality and Operations Assurance Specialist at Stanlow Terminals

Tell us a little about your career before you joined Stanlow Terminals Having spent over a decade in the oil and gas industry, I’ve been in my current position as a Quality and Operations Assurance Specialist for nearly a year. In 2022, I relocated from the Philippines to the UK, where I initially worked at […]

Looking to the future

Mike Gaynon, CEO at Stanlow Terminals Limited recently sat down with Molly Cooper from Tank Storage to explore the prospects for Stanlow Terminals in 2024. Delving into the future, the discussion illuminated how Stanlow Terminals are strategically positioned to spearhead the national drive in evolving energy infrastructure, with ambitious plans to establish the UK’s first […]

Buoyant partnership makes a splash for the future of the maritime logistics industry

In the dynamic landscape of maritime logistics, the synergy between companies can be the catalyst for innovation and growth. Our collaboration with local ship building business, Cammell Laird, exemplifies this ethos. Our journey with Cammell Laird began with the initial fabrication of a single Marine Mooring Dolphin in 2022, a successful venture which has led […]

Stanlow Terminals and Eni UK sign a MOU to develop carbon dioxide transport and storage projects

Stanlow Terminals Ltd (“Stanlow Terminals”), the UK’s largest independent bulk liquid storage provider has signed a Memorandum of Understanding (MoU) with Eni UK Ltd (“Eni UK”), the UK subsidiary of global energy company Eni, to explore the development of carbon dioxide (CO2) collection, shipping, and storage at the Stanlow Terminal location and then delivering the […]

Stanlow Terminals is Transforming for Tomorrow

At Stanlow Terminals we are investing to transform our assets to make these opportunities a reality by: ➡️Growing our biofuels (HVO, SAF, Bio-Methanol & Bio-Ethanol) storage offering to customers in our Biofuels Hub. ➡️Building a Hydrogen Transport Hub, which will allow distribution of Hydrogen by road, rail and sea. ➡️Working with partners to develop CO2 […]

Very Large Crude Carrier docks at Tranmere

For the first time in close to a decade we got a partly loaded VLCC into Tranmere port recently. The vessel Sea Pearl with over 1 million barrels of crude docked safely at the port and is presently unloading West Texas Intermediate crude from the US. A very big thank you to our Marine team at Stanlow […]

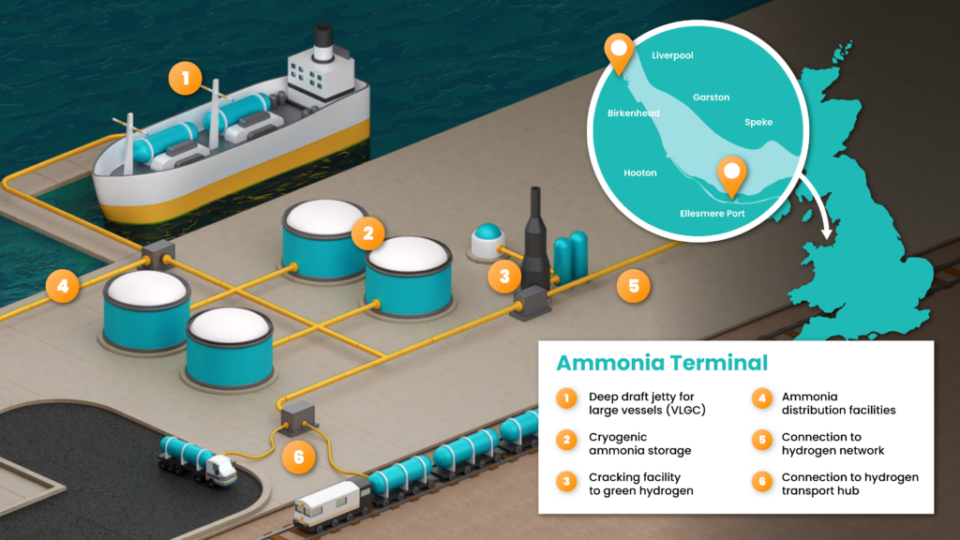

Stanlow Terminals at the heart of global hydrogen energy transition with development of open access green ammonia import terminal

Stanlow Terminals Ltd has announced they are to develop a major new open access import terminal for green ammonia in the Port of Liverpool. The new terminal, which will be an expansion of Stanlow Terminal’s existing facilities, will provide the connecting infrastructure to enable significant volumes of green ammonia to be imported into the UK. […]

Stanlow Terminals (STL) shortlisted for Global Storage Tank Storage Awards

We are delighted to announce that Stanlow Terminals has been recognised for the great work they are doing and dedication to preparing for the energy transition and working towards reaching netzero. They have been shortlisted in the Terminal of the Future category of this year’s Global Tank Storage Awards, being held at StocExpo in Rotterdam later this year. […]

Stanlow Terminals Secures Biofuels Certification

Stanlow Terminals Ltd has achieved another key accreditation as it develops its biofuels hub to deliver a low carbon future. The organisation has gained certification as a sustainable warehouse facility provider for the storage of bio-based feedstocks and biofuels under the International Sustainability & Carbon Certification (ISCC) from SGS. Stanlow Terminals is committed to comply […]

Ship-to-ship fuel transfer unveiled at Tranmere Terminal

New service to boost capacity, efficiency and environmental performance Stanlow Terminals Ltd has announced it is launching a new ship-to-ship (STS) fuel transfer service on the River Mersey in partnership with Peel Ports Group (PPG). The STS Transfers will enable larger ships to transport products directly from Tranmere to a wide range of international destinations. […]

Stanlow Terminals is bringing an exciting new energy hub to the UK

Read Energy, Oil & Gas Magazine’s latest edition featuring an interview with Michael Gaynon, Chief Executive of Stanlow Terminals talking about how the company is driven to support the country’s net-zero ambitions. https://issuu.com/schofieldpublishingltd/docs/eog209/56

Stanlow Terminals gains further international standards accreditation

As we continue to strive to meet the highest standards in our environmental performance, we’re proud to announce that we have been awarded the ISO 14001:2015 Environmental Management System accreditation. The certification covers all of the environmentally sensitive aspects of our business, including how we manage and distribute crude products, refined petroleum products, petrochemical products, […]

Stanlow Terminals Welcomes our Chairman, Prashant Ruia

We recently welcomed the chair of the board of Directors, Prashant Ruia, to Stanlow Terminals for a tour of our facilities and to discuss in more detail our plans to create a sustainable, industry-leading product offering. It was fantastic to show him around our site and lay out our vision for the future. One part […]

Stanlow Terminals gain International accreditations

Stanlow Terminals continues to gain International Standard accreditations In continuance with our strive to offer the highest possible standards, Stanlow Terminals are pleased to announce that our Management Systems has been accredited to the International Standard ISO9001 – Quality Management Systems and ISO14001 Environmental Management Systems following a thorough audit process conducted by DNV GL. […]

Stanlow Terminals investing in Biofuels storage facility

Stanlow Terminals to invest in developing the UK’s largest new Biofuels Storage Hub for NW England Stanlow Terminals Limited (STL) today announced it will make investments over the next three years to develop the UK’s largest biofuels storage hub located in the North West of England. The major investment is a key pillar in Stanlow […]