Challenges in store: How existing fuel storage and transport infrastructure is crucial to achieving net-zero

Stanlow Manufacturing Complex has been producing fuels for the United Kingdom for the last 60 years. Patrick Walters explains the fundamental role this existing infrastructure can play in creating a Sustainable Energy Hub of the future.

The UK Government has set out its Ten Point Plan for a Green Industrial Revolution which will keep the UK leading worldwide innovation in establishing a net-zero future. I believe the Tank Storage Industry will play a key part in the country achieving these goals.

Increasing reliance on Biofuels

As the UK transitions to Zero-Emission Vehicles there will undoubtedly be changes in the fuel we use. Taking into account the practical issues for HGV’s, aviation and the maritime sector, liquid fuel sources will remain in place as part of the net-zero solutions of the future. We can already see a shift towards electrification of vehicles, and while technology advancement is making greater numbers of electric cars available, it will be many years until the private and commercial ICE fleets are fully transitioned.

As part of bridging this gap the UK Government recently announced an increase to 10% Ethanol in petrol to come into force this year. This change is the equivalent of taking 350,000 cars off the road having an immediate effect on emissions hugely welcomed by the industry.

From a storage and logistics perspective, this has resulted in increased demand for Ethanol storage to ensure supply can keep up with consumer demand. These tanks require specialist linings to avoid corrosion and to manage HSSE requirements.

Stanlow Terminals has been working with coatings specialists to develop a suite of linings now being deployed, for multiple biofuel components to re-life existing infrastructure for these new greener fuels. This allows the repurposing of currently unused infrastructure originally built to handle products like fuel oil, a fuel supply in decline.

The fact that existing unused infrastructure can be repurposed has enabled us to provide a faster more economical solution to increasing capacity requirements for this new growing market.

Greener Aviation

As previously mentioned the aviation industry has fundamental challenges in moving away from a traditional liquid fuel particularly with long haul flights and low temperatures at altitude. Therefore it is commonly agreed that a more traditional fuel will continue to be required in this sector. Innovation has therefore been focused on technology to produce a synthetic alternative fuel from a sustainable feedstock.

Sustainable Aviation Fuels (SAF) of the future will have similar chemical properties to existing Jet fuels therefore not bring with them the challenges of other new fuels in their storage and transportation requirements, meaning existing infrastructure can be used.

Existing infrastructure links was a major factor in Fulcrum BioEnergy selecting Stanlow for the location of their planned SAF Bio-Refinery. Fulcrum, a pioneer in making low-carbon fuels from non-recyclable household waste is due to complete construction of their US plant this year.

The fact that Stanlow has storage tank capacity, development land and links to the existing Manchester Jet Line, the underground pipeline linking Stanlow Terminals to Manchester Airport, made it the primary choice for the development.

Re-tooling for Hydrogen & Carbon Capture

The fuel that is earmarked to play the most important part in the UK achieving net-zero is hydrogen, this is reflected by the prominence the government gave the fuel in its latest energy white paper.

The HyNet project already at an advanced stage of development provides one blueprint for the future. Under its proposals, blue hydrogen – produced from natural gas whilst capturing all CO2 generated from the process – will be produced at Stanlow providing a net-zero fuel to decarbonise industry and heat UK homes. This fundamental change in how we fuel the country will bring significant new requirements for storage and transportation.

One of the uses of hydrogen set out is a net-zero replacement for diesel to fuel HGV’s of the future. In order for a seamless transition to this new fuel a network of fuelling stations will need to be established and ongoing supply methods established. Following this change through the supply chain to source, there will need to be developments in suitable storage, pipelines, road, rail and marine infrastructure. An exciting but substantial change to the industry.

In order to ensure a secure supply of natural gas to feed the blue hydrogen plant it is also likely investment will be required in new regional LNG (Liquefied Natural Gas) import terminals accompanied by LNG storage tanks fed directly into the plant. Once the hydrogen is produced there will be a requirement to capture and store all carbon produced from the process and this is where Stanlow Terminals can provide a unique solution utilising existing currently unused infrastructure.

Depleted gas reservoirs under the seabed in Liverpool Bay which were once used to supply natural gas to the UK now form vast empty caverns and are proposed as the location for CO2 storage. Offshore and onshore gas extraction assets with direct pipeline links to the Stanlow site will be repurposed to move CO2 to Liverpool Bay ensuring no carbon is released into the atmosphere during hydrogen production.

This opens up further opportunity for Stanlow Terminals to potentially establish wider access to these storage caverns and enable industry to capture CO2 produced at manufacturing and processing sites around the UK and deliver by road, rail or ship into Stanlow Terminals to ensure safe storage of CO2.

The Green Industrial Revolution

This is why I know that the bulk liquid storage industry will play a major role in achieving net-zero targets by supporting and developing the Sustainable Energy Hubs of the future. The storage and distribution of future fuels, energy sources and CO2 to meet consumer demand while protecting the environment will be a fundamental pillar of UK society and a supply chain ensuring minimal disruption to consumers and industry while maintaining key environmental requirements will be vital in maintaining day to day life as we know it. We should all be very proud of the role we are taking in the UK’s Green Industrial Revolution.

Related News

A Day in the Life of Chris Legerton – Terminal Manager/ Terminal Operations Manager

Full name: Chris Legerton How long have you been at Stanlow Terminals for? I’ve worked at Stanlow Terminals twice in my career. Initially as a Shift Transport Manager from 1993 to 1999, and then from 2009 onwards in my current role. In the early days, I managed the terminal and road tanker operations. Stanlow operated […]

A Day in the Life of Alyssa Usman, Quality and Operations Assurance Specialist at Stanlow Terminals

Tell us a little about your career before you joined Stanlow Terminals Having spent over a decade in the oil and gas industry, I’ve been in my current position as a Quality and Operations Assurance Specialist for nearly a year. In 2022, I relocated from the Philippines to the UK, where I initially worked at […]

Stanlow Terminals CEO Mike Gaynon Discusses Award-Winning Plans for UK’s First Sustainable Energy Hub

Mike Gaynon, CEO at Stanlow Terminals Limited recently sat down with Molly Cooper from Tank Storage following Stanlow Terminals winning the prestigious ‘Terminal of the Future Award’ in Rotterdam. The discussion illuminated how Stanlow Terminals are strategically positioned to spearhead the national drive in evolving energy infrastructure, with the award winning terminal’s ambitious plans to […]

Buoyant partnership makes a splash for the future of the maritime logistics industry

In the dynamic landscape of maritime logistics, the synergy between companies can be the catalyst for innovation and growth. Our collaboration with local ship building business, Cammell Laird, exemplifies this ethos. Our journey with Cammell Laird began with the initial fabrication of a single Marine Mooring Dolphin in 2022, a successful venture which has led […]

Stanlow Terminals and Eni UK sign a MOU to develop carbon dioxide transport and storage projects

Stanlow Terminals Ltd (“Stanlow Terminals”), the UK’s largest independent bulk liquid storage provider has signed a Memorandum of Understanding (MoU) with Eni UK Ltd (“Eni UK”), the UK subsidiary of global energy company Eni, to explore the development of carbon dioxide (CO2) collection, shipping, and storage at the Stanlow Terminal location and then delivering the […]

Stanlow Terminals is Transforming for Tomorrow

At Stanlow Terminals we are investing to transform our assets to make these opportunities a reality by: ➡️Growing our biofuels (HVO, SAF, Bio-Methanol & Bio-Ethanol) storage offering to customers in our Biofuels Hub. ➡️Building a Hydrogen Transport Hub, which will allow distribution of Hydrogen by road, rail and sea. ➡️Working with partners to develop CO2 […]

Very Large Crude Carrier docks at Tranmere

For the first time in close to a decade we got a partly loaded VLCC into Tranmere port recently. The vessel Sea Pearl with over 1 million barrels of crude docked safely at the port and is presently unloading West Texas Intermediate crude from the US. A very big thank you to our Marine team at Stanlow […]

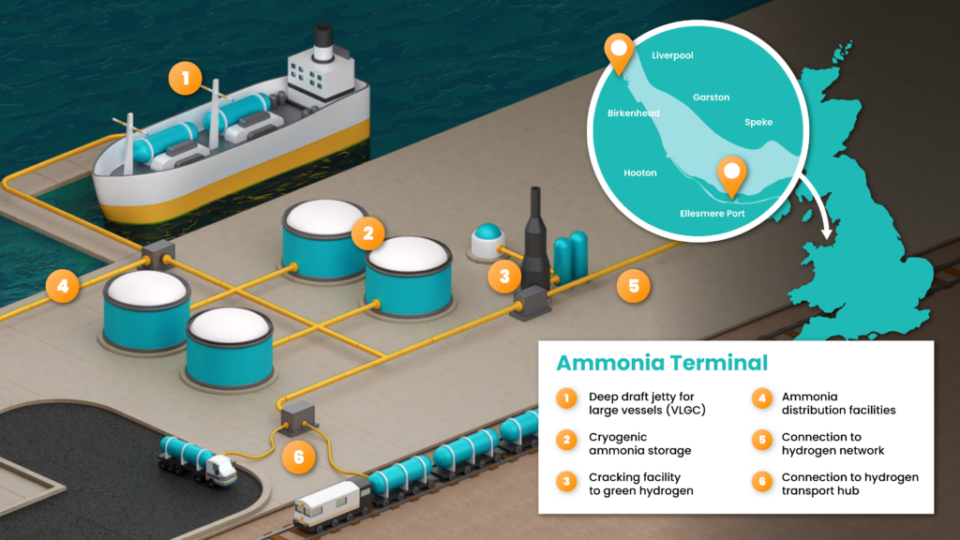

Stanlow Terminals at the heart of global hydrogen energy transition with development of open access green ammonia import terminal

Stanlow Terminals Ltd has announced they are to develop a major new open access import terminal for green ammonia in the Port of Liverpool. The new terminal, which will be an expansion of Stanlow Terminal’s existing facilities, will provide the connecting infrastructure to enable significant volumes of green ammonia to be imported into the UK. […]

Stanlow Terminals (STL) shortlisted for Global Storage Tank Storage Awards

We are delighted to announce that Stanlow Terminals has been recognised for the great work they are doing and dedication to preparing for the energy transition and working towards reaching netzero. They have been shortlisted in the Terminal of the Future category of this year’s Global Tank Storage Awards, being held at StocExpo in Rotterdam later this year. […]

Stanlow Terminals Secures Biofuels Certification

Stanlow Terminals Ltd has achieved another key accreditation as it develops its biofuels hub to deliver a low carbon future. The organisation has gained certification as a sustainable warehouse facility provider for the storage of bio-based feedstocks and biofuels under the International Sustainability & Carbon Certification (ISCC) from SGS. Stanlow Terminals is committed to comply […]

Ship-to-ship fuel transfer unveiled at Tranmere Terminal

New service to boost capacity, efficiency and environmental performance Stanlow Terminals Ltd has announced it is launching a new ship-to-ship (STS) fuel transfer service on the River Mersey in partnership with Peel Ports Group (PPG). The STS Transfers will enable larger ships to transport products directly from Tranmere to a wide range of international destinations. […]

Stanlow Terminals is bringing an exciting new energy hub to the UK

Read Energy, Oil & Gas Magazine’s latest edition featuring an interview with Michael Gaynon, Chief Executive of Stanlow Terminals talking about how the company is driven to support the country’s net-zero ambitions. https://issuu.com/schofieldpublishingltd/docs/eog209/56

Stanlow Terminals gains further international standards accreditation

As we continue to strive to meet the highest standards in our environmental performance, we’re proud to announce that we have been awarded the ISO 14001:2015 Environmental Management System accreditation. The certification covers all of the environmentally sensitive aspects of our business, including how we manage and distribute crude products, refined petroleum products, petrochemical products, […]

Stanlow Terminals Welcomes our Chairman, Prashant Ruia

We recently welcomed the chair of the board of Directors, Prashant Ruia, to Stanlow Terminals for a tour of our facilities and to discuss in more detail our plans to create a sustainable, industry-leading product offering. It was fantastic to show him around our site and lay out our vision for the future. One part […]

Q&A with our HSSE Manager

Our Health, Safety, Security and Environment (HSSE) Manager Lee Deponeo heads up our work to safeguard best practice across the business. His team ensures the very highest standards are upheld as we develop the sustainable energy hub of the future. Lee has more than 15 years’ experience in the health and safety department at Stanlow […]